Product Description

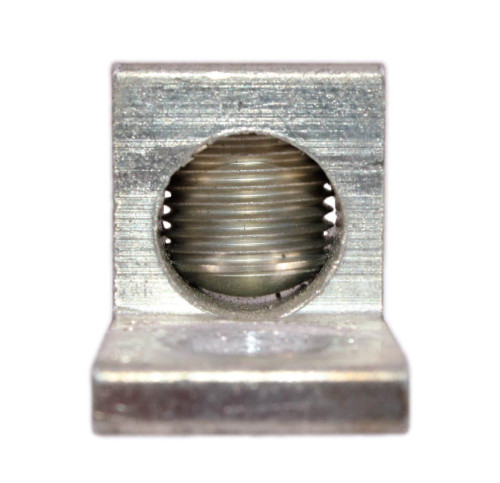

The AD250 is a heavy-duty, dual-barrel aluminum mechanical terminal lug designed for high-capacity power distribution. Engineered to terminate two separate conductors into a single mounting point, this lug is a staple in industrial switchgear, motor control centers, and panelboards where high-density wiring and reliability are non-negotiable.

Manufactured from high-strength 6061-T6 aluminum alloy and finished with electro-tin plating, the AD250 provides maximum conductivity and superior resistance to oxidation. Its CU9AL (AL9CU) dual-rating ensures it is fully certified for use with both copper and aluminum conductors in demanding 600V to 35kV applications.

Technical Specifications

-

Manufacturer: Homac / Blackburn (ABB)

-

Part Number: AD250

-

Configuration: 2-Barrel (2 Ports)

-

Conductor Range: 6 AWG up to 250 kcmil (MCM)

-

Material: High-Strength 6061-T6 Aluminum Alloy

-

Finish: Electro-Tin Plated

-

Rating: Dual-Rated CU9AL (AL9CU)

-

Temperature Rating: 90°C (194°F)

-

Voltage Rating: 600V (Standard) to 35kV (with proper insulation/spacing)

-

Mounting Hole Size: 3/8-inch (13/32" actual)

-

Termination Type: Mechanical Screw-Type

-

Length: 2.24 inches

-

Width: 1.64 inches

-

Height: 1.26 inches

Key Features & Benefits

-

Space-Saving 2-Barrel Design: Consolidate two large 250 MCM feeders into a single mounting footprint, ideal for compact busbar and enclosure layouts.

-

Universal CU9AL Compatibility: Certified for both Copper (Cu) and Aluminum (Al) conductors, providing total field flexibility and preventing galvanic corrosion.

-

Superior Corrosion Resistance: The electro-tin plated finish provides a durable barrier against atmospheric oxidation, maintaining low contact resistance over the life of the connection.

-

Mechanical Efficiency: Features high-torque mechanical set screws that allow for secure termination using standard tools—no hydraulic crimping required.

-

Industrial Durability: Constructed from extruded aluminum for higher structural integrity than cast alternatives, ensuring the lug won't crack during high-torque installation.