Product Description

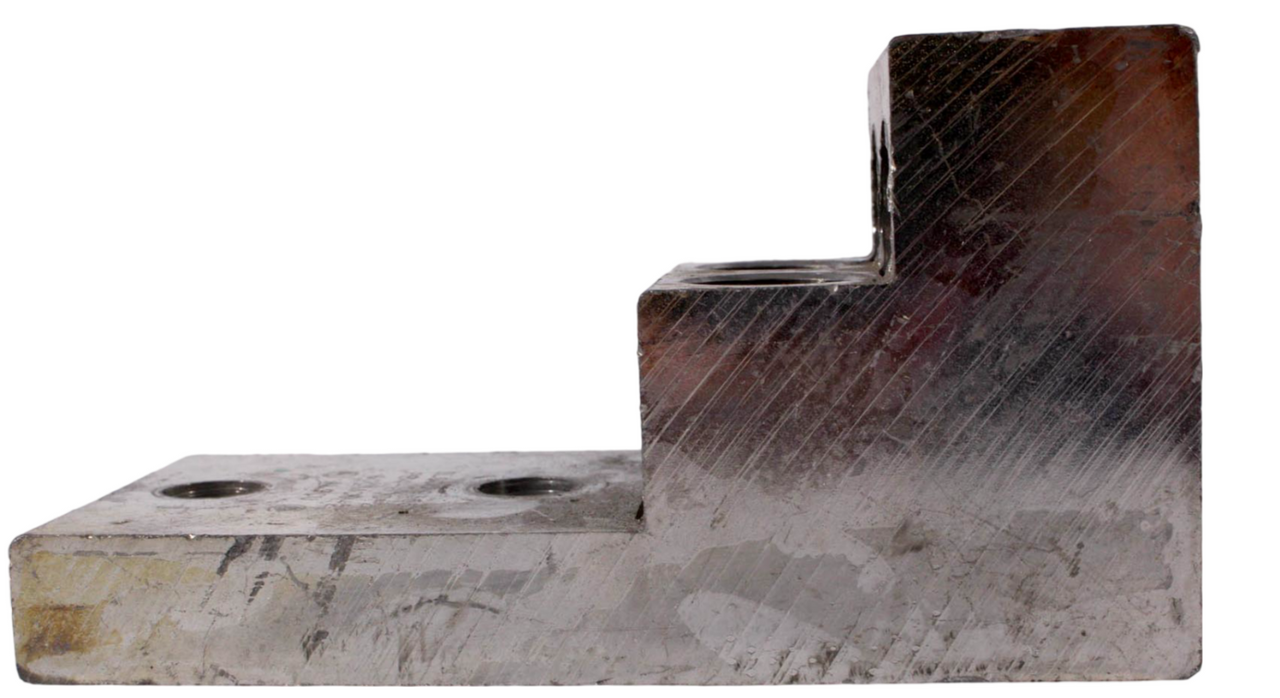

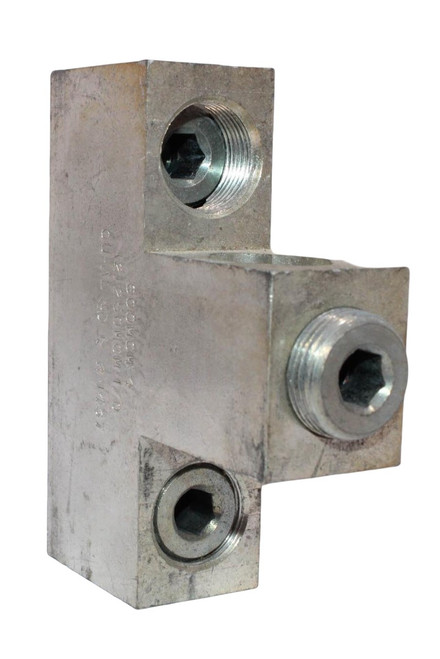

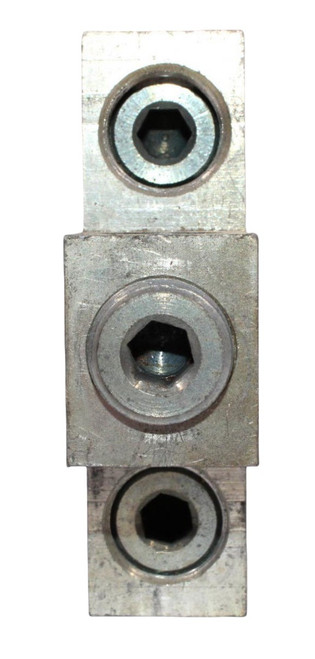

The Ilsco PB4-600-2N is a heavy-duty, space-saving mechanical terminal designed for high-density power distribution. Featuring a specialized stacked 4-port design, this lug allows you to terminate four large-gauge conductors in a fraction of the horizontal busbar space required by traditional side-by-side lugs.

Precision-machined from high-strength 6061-T6 aluminum alloy and electro-tin plated, the PB4-600-2N is AL9CU dual-rated for both copper and aluminum conductors. Its 2-hole NEMA mounting configuration ensures maximum surface contact and superior anti-rotation stability for mission-critical industrial applications.

Technical Specifications

-

Manufacturer: Ilsco

-

Part Number: PB4-600-2N

-

Configuration: 4-Port / 4-Conductor (Stacked)

-

Conductor Range: 600 kcmil (MCM) down to 2 AWG (Copper or Aluminum)

-

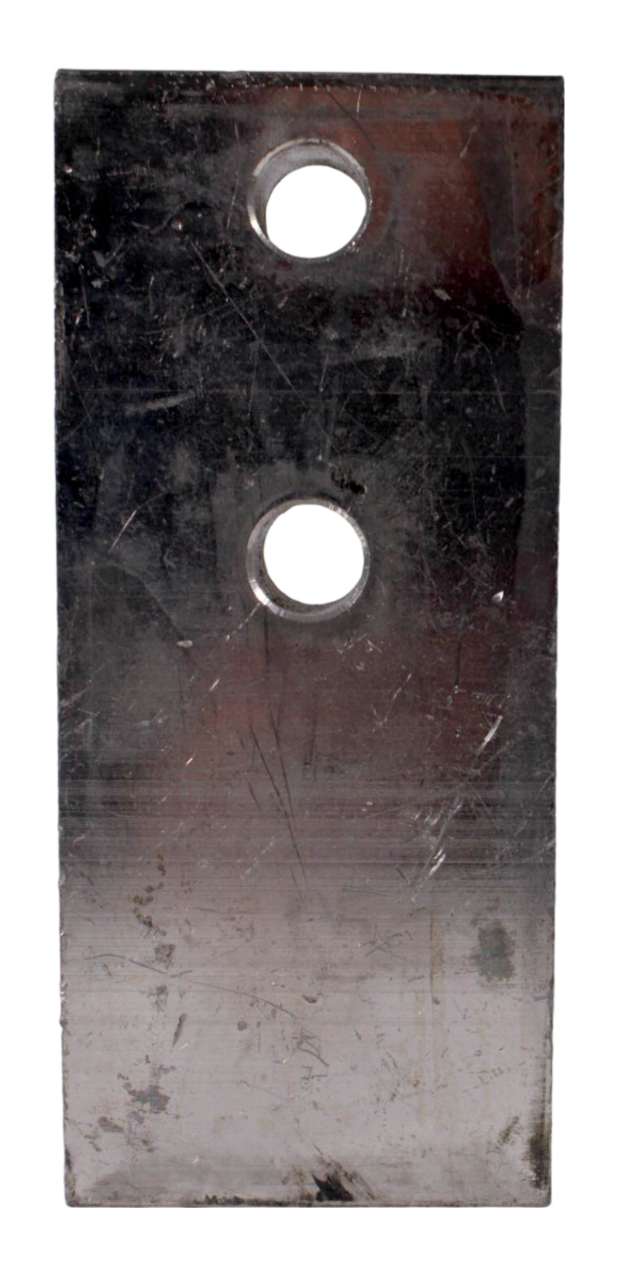

Mounting Pad: 2-Hole NEMA Standard

-

Stud/Bolt Size: 1/2"

-

Hole Spacing: 1-3/4" Center-to-Center

-

Material: 6061-T6 High-Strength Aluminum Alloy

-

Plating: Electro-Tin Plated (Corrosion Resistant)

-

Voltage Rating: 600V (Up to 35kV with proper insulation)

-

Temperature Rating: 90°C

-

Drive Size: 1/2" Hex Drive

Key Features & Benefits

-

Space-Efficient Stacked Design: Provides four termination ports in a vertical stack, significantly reducing the footprint required on switchgear busbars and transformer pads.

-

Universal AL9CU Rating: Fully certified for use with both Copper (Cu) and Aluminum (Al) conductors, providing ultimate flexibility for any installation site.

-

Easy Wire Insertion: Features a chamfered wire entry at each port, preventing strand "hang-up" and making the installation of heavy 600 MCM cable smooth and fast.

-

Maximum Conductivity: The electro-tin plating ensures a low-resistance electrical path and protects against galvanic corrosion in harsh environments.

-

NEMA Standard Mounting: The 1-3/4" hole spacing is the industry standard for industrial-grade power distribution equipment, ensuring a perfect fit for existing bus systems.

⚙️ Typical Applications

-

Industrial Panelboards: Consolidating multiple feeder lines into a single main connection point.

-

Transformer Secondary Taps: Terminating large-gauge cables in outdoor utility or indoor facility transformers.

-

Motor Control Centers (MCC): Providing high-amperage power feeds to large industrial machinery.

-

Switchgear Overhauls: Upgrading existing systems to handle higher conductor counts without replacing the entire busbar.

Technical Installation Notes

-

Hex Size: A 1/2" hex (Allen) wrench is required for the mechanical set screws.

-

Torque Requirement: For 600 MCM conductors, recommended torque is typically 375–500 in-lbs. Always verify the torque value printed on the lug body for safety.

-

Oxide Inhibitor: As with all aluminum terminations, the use of a quality joint compound (like Penetrox) is highly recommended to ensure a gas-tight, long-term connection.