Product Description

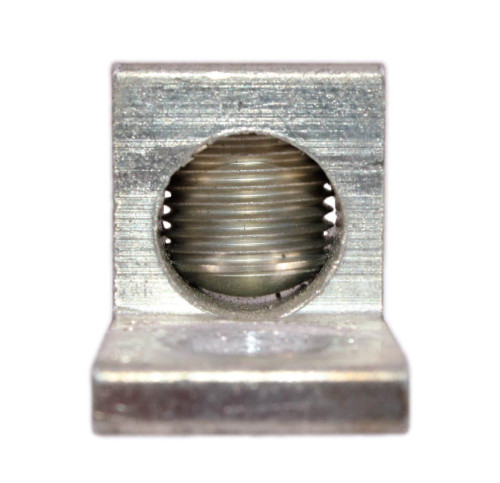

The INT RU-600-3 is a heavy-duty, triple-barrel mechanical terminal lug designed for high-capacity industrial power distribution. This component allows for the secure termination of up to three large-gauge conductors in a single compact block, making it an essential space-saving solution for panelboards, switchgear, and motor control centers.

Precision-machined from high-strength aluminum alloy and finished with electro-tin plating, this lug ensures a low-resistance connection and superior protection against oxidation. Its CU-AL dual-rating provides total flexibility, allowing for use with both copper and aluminum conductors.

Technical Specifications

-

Part Number: RU-600-3

-

Manufacturer: INT (Industrial Network Terminals)

-

Type: Mechanical Terminal Lug (Set Screw)

-

Configuration: 3-Port / Triple Barrel (Stacked/Side-by-Side)

-

Conductor Range: 600 MCM (kcmil) down to 3 AWG

-

Material: High-Strength 6061-T6 Aluminum Alloy

-

Plating: Electro-Tin Plated (prevents corrosion)

-

Mounting: 1-Hole Mounting Pad

-

Stud/Bolt Size: 3/8" (Standard)

-

Rating: CU-AL Dual Rated (Copper and Aluminum)

-

Voltage Rating: 600V (Standard)

-

Temperature Rating: 90°C

Key Features & Benefits

-

Triple Conductor Capacity: Streamlines wiring by allowing three separate cables to be terminated on a single mounting point, significantly reducing the footprint on busbars.

-

Dual-Rated Versatility: Certified for use with both Copper (Cu) and Aluminum (Al) conductors, minimizing the need for multiple part types on-site.

-

Robust Mechanical Connection: Utilizes high-pressure set screws to ensure a gas-tight electrical bond without the need for specialized hydraulic crimping tools.

-

Superior Corrosion Resistance: The tin-plated finish prevents galvanic corrosion, especially important when joining dissimilar metals (aluminum lugs to copper busbars).

-

Industrial Durability: Designed to handle the high thermal and mechanical stresses associated with 600 MCM cabling in commercial and industrial settings.

Technical Installation Tips

-

Torque Requirement: For 600 MCM conductors, typical installation torque ranges from 375 to 500 in-lbs. Always check the specific manufacturer labeling for final torque values to ensure a safe connection.

-

Wire Preparation: For aluminum conductors, it is highly recommended to use a quality oxide inhibitor (like Penetrox) to ensure long-term electrical stability.

-

Space Management: The single-hole mounting design is ideal for retrofitting existing panels where busbar space is limited but multiple cable feeds are required.