Product Description

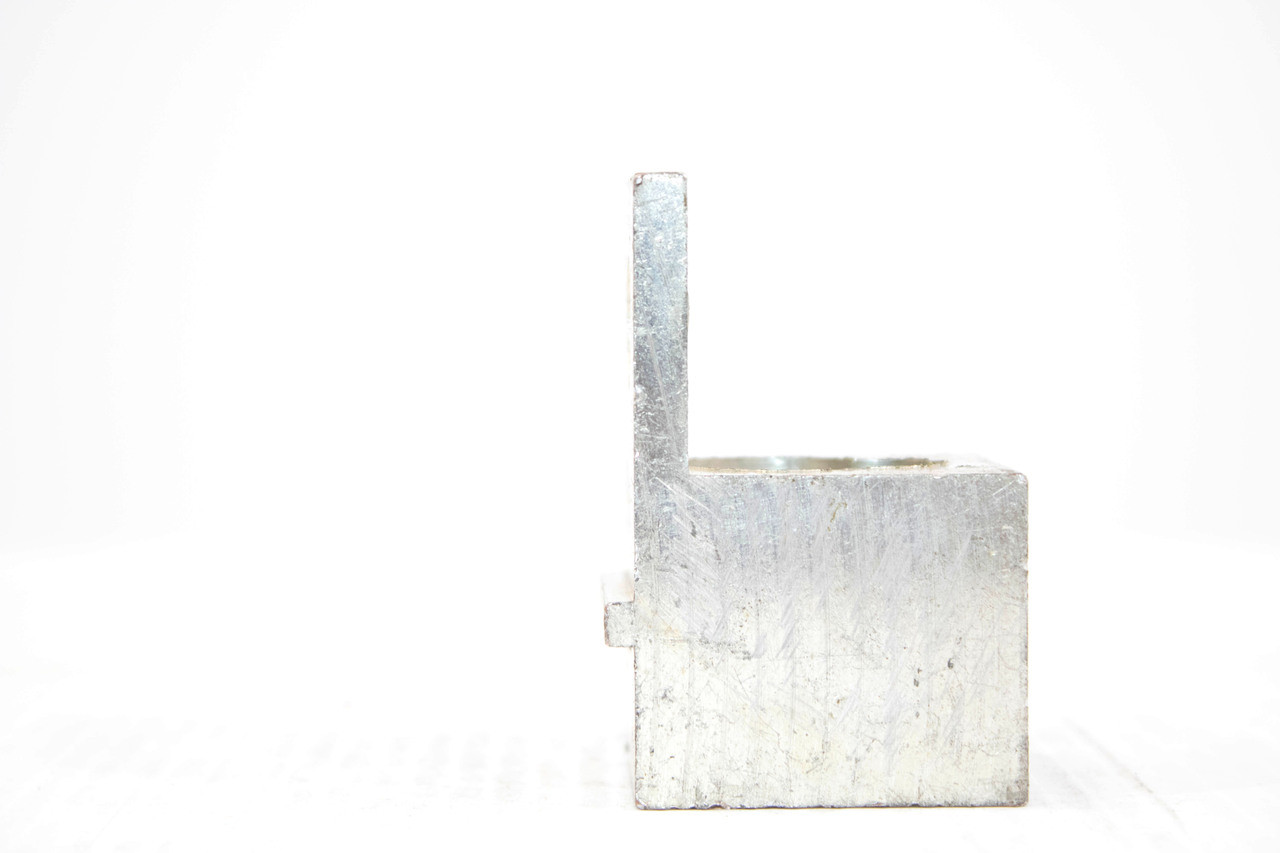

The Square D DCC C-419 is an industrial-grade, heavy-duty mechanical terminal lug engineered for reliable power distribution. Precision-machined from high-strength 6061-T6 extruded aluminum alloy, this lug is designed for use in Square D panelboards, switchgear, and neutral assemblies. It features a robust single-barrel design capable of terminating large-diameter main feeders up to 600 kcmil (MCM) or dual parallel conductors in specific configurations.

Every DCC C-419 is finished with premium electro-tin plating to ensure exceptionally low contact resistance and to provide a permanent barrier against oxidation and galvanic corrosion. As a dual-rated (AL9CU) connector, it is certified for the safe termination of both copper and aluminum conductors.

Technical Specifications

-

Manufacturer: Square D (Schneider Electric)

-

Part Number: DCC C-419

-

Conductor Range (Single): 2 AWG up to 600 kcmil (MCM)

-

Conductor Range (Double): Rated for (2) 1/0 AWG to 250 kcmil

-

Material: High-Strength Extruded Aluminum Alloy

-

Finish: Electro-Tin Plated (Corrosion Resistant)

-

Rating: Dual-Rated AL9CU (Compatible with Al/Cu)

-

Voltage Rating: 600V (Standard) / Up to 35kV (High-Voltage with proper insulation)

-

Temperature Rating: 90°C (194°F)

-

Mounting Configuration: Single Hole (Fits 5/8-inch Stud)

Physical Dimensions & Design

-

Heavy-Duty Tang: Features an oversized 5/8-inch mounting hole designed for high-torque applications and maximum current transfer to the busbar.

-

Versatile Barrel: Engineered with a deep wire chamber to provide maximum surface contact for 600 MCM feeders or dual 250 MCM parallel runs.

Key Features & Benefits

-

OEM Specification: Designed to meet the exact tolerances of Square D / Schneider Electric electrical equipment for seamless fit and code compliance.

-

Large Stud Capacity: The 5/8-inch mounting hole allows for much higher mechanical torque and structural security than standard 1/2-inch lugs.

-

Mechanical Efficiency: Features a rugged internal hex set-screw that provides high-pressure termination—eliminating the need for expensive hydraulic crimping tools or specialized dies.

-

Bimetallic Protection: The tin-plating allows for safe copper-to-aluminum transitions, preventing the thermal expansion failures common in untreated terminals.

-

Industrial Durability: Extruded aluminum construction offers superior structural integrity under thermal cycling compared to cast alternatives.